CPQ interface with CRM system

A CRM system is a first step in professionalisation for most organisations. Not surprising as it helps to better anticipate customer needs by providing access to customer contact history. A CPQ link with your CRM system is therefore quite basic, but very crucial as it allows you to gain insight into future sales.

This is what this link looks like: The CRM system provides input (contact information) for the configurator. The configurator uses the input to create a quotation (output of the configurator) and then sends it back to the CRM system. Thus, thanks to the link, you keep track of your sent (open) quotations and the values of the quotation.

Product configurator with ERP linkage

Where an ERP system helps you automate and manage key business processes for optimal performance, CPQ software provides an offer where your margin is guarded. Not the CPQ-software but your ERP system remains the basis for all your item information (think cost price, selling price, purchase price, material price, etc.), but also information about the delivery and/or production of the order. And that is exactly why this link is so relevant.

This is what the link looks like: the ERP system provides input (article information) to the product configurator, which then converts this into customer-specific order information (configurator output). This in turn serves as input for the ERP system, such as parts lists and sales prices. In short, an essential link to monitor the error margin, but also your profit margin. Especially if you supply complex or customised products.

CAD system linking with configurator

Besides the perhaps logical links of CPQ software with CRM and ERP systems, linking with a CAD system is actually quite simple too. As long as the possible parameters are properly defined in the configurator, they can be used by your CAD system. This allows you to automatically produce production drawings after your customer’s product configuration.

This is what this link looks like: possible parameters (possible length and width dimensions, diameter, etc.) are defined in the product configurator. The customer (or your dealers, field service, etc.) configures his or her product using these parameters. The configuration can then easily be used to feed CAD systems. For the configurator, calculating dozens or hundreds of additional values is no problem at all. And all CAD systems (often already in the free basic version) have the possibility of reading parameter files.

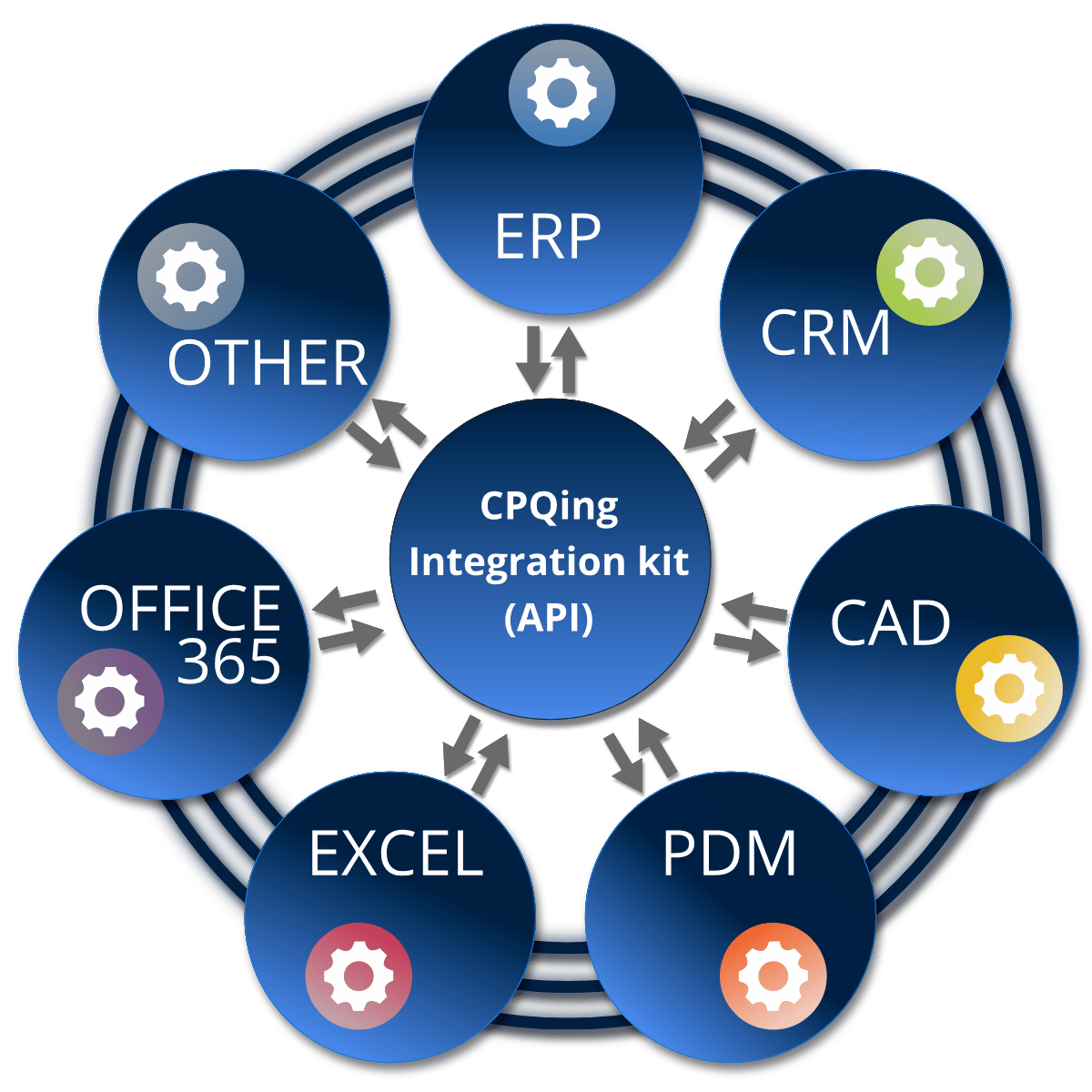

Other links of our CPQ software

Besides the links highlighted above, our CPQ software can also be linked to other systems. Therefore, we would like to mention a few more interfaces we are proud of. For example, the CAM link (the configurator’s control of CNC machines) used by Eribel Solid. Here, the configurator provides the saw optimisation programme with parameters, ensuring optimal production. This saves at least 2 FTEs! But links to eCommerce platforms are also possible and even digital signing is an option. The possible links are therefore endless as far as we are concerned. Even if an API or web protocol is missing, a link can often still be set up in another way.

What would you like to link our product configurator to? Contact our specialists and we will be happy to think along with you!