Optimise and accelerate

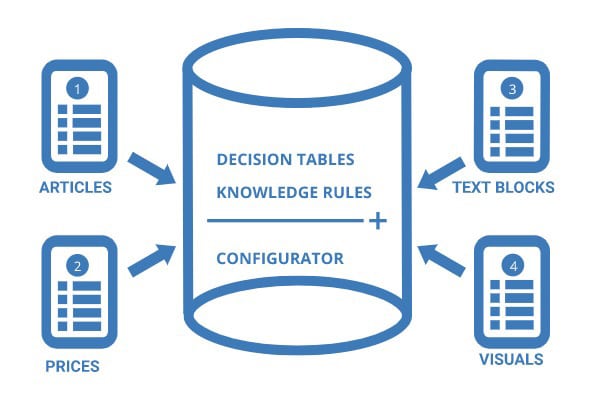

This also applies to building supply companies. Indeed, many products within the construction supply industry are perfectly configurable (think window frames, doors, washbasins, air conditioners, etc.). This means that a configurator can optimise and speed up a lot of processes in this sector. A lot of building supply companies also want a configurator integrate with their website, so that customers can explore all the éone and all for themselves. Furtherthe software also ensures that quotations are converted into producible orders. While entering all characteristics, work preparation is done in real time in the background. So you and your customers always have instant access to the current price.

3D-visualisations

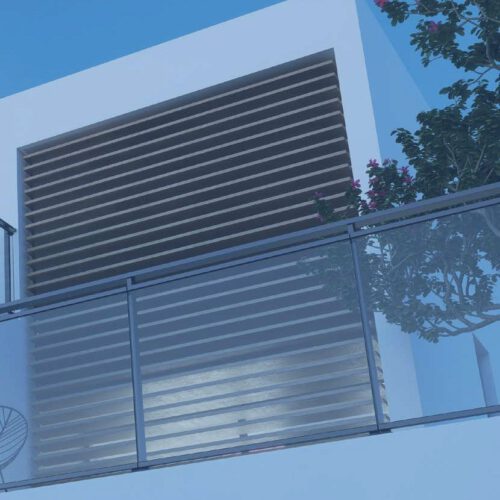

Not only in processes can the software provide substantial improvements, a configurator can also provide 2D or 3D visualisations. Based on the features entered, your customers can instantly see how certain choices will affect the final product.

Our customers have their say

Several of our customers are construction supply companies. Below, we take you through two stories.

Staka Metallics is a major s

As a continuous forerunner in the modernisation of their market, Staka wanted the customer to be able to see an instant 3D visualisation of the resulting product at product assembly, which then changes in real time with the chosen specifications. This now also allows the customer to compose special sizes from the website, which are then fed directly into the ERP system.

With more than 25 years of craftsmanship, Eribel Solid is an experienced and reliable project partner in the production of door frame. The company produces the frames for doors sold by parent company Eribel.

Eribel sends Eribel Solid an Excel file containing the door specifications, which CPQing’s configurator then reads.Based on this Excel import, CPQing’s configurator then automatically configures

ch all window frames. Finally, the configurator generates a material and routing list. The routing list is used to provide a saw optimisation package with data so that actual production can take place.

Eribel Solid additionally chose CPQing because the software is also used as a calculation tool.This ensures that Eribel can calculate in advance what the costs will be for the production of the frames. This then leads to a price overview.

The benefits are endless

The implementation of a configurator is different for every company and can vary by industry. However, there are benefits that are the same for every company in every industry, regardless of the application:

- Visual purchase guidance for customer

- Professional appearance

- Guaranteed correct offers (offers always producible)

- Always have instant insight into all standards and limitations of all products or services

- Complex products are displayed simply and clearly

- Controlling the content of the quotation document

- Possibility to configure (and sell)

- Turnaround time is significantly reduced (from quotation to production)

- Less failure costs

- Easily expandable

- Direct insight into cost and delivery times of variations

Do you also want your building supply company to be able to use all the advantages of a configurator soon? Then feel free to contact us to discuss the possibilities, or experience the convenience for yourself with your own demo environment.